OUR EXPERTISE

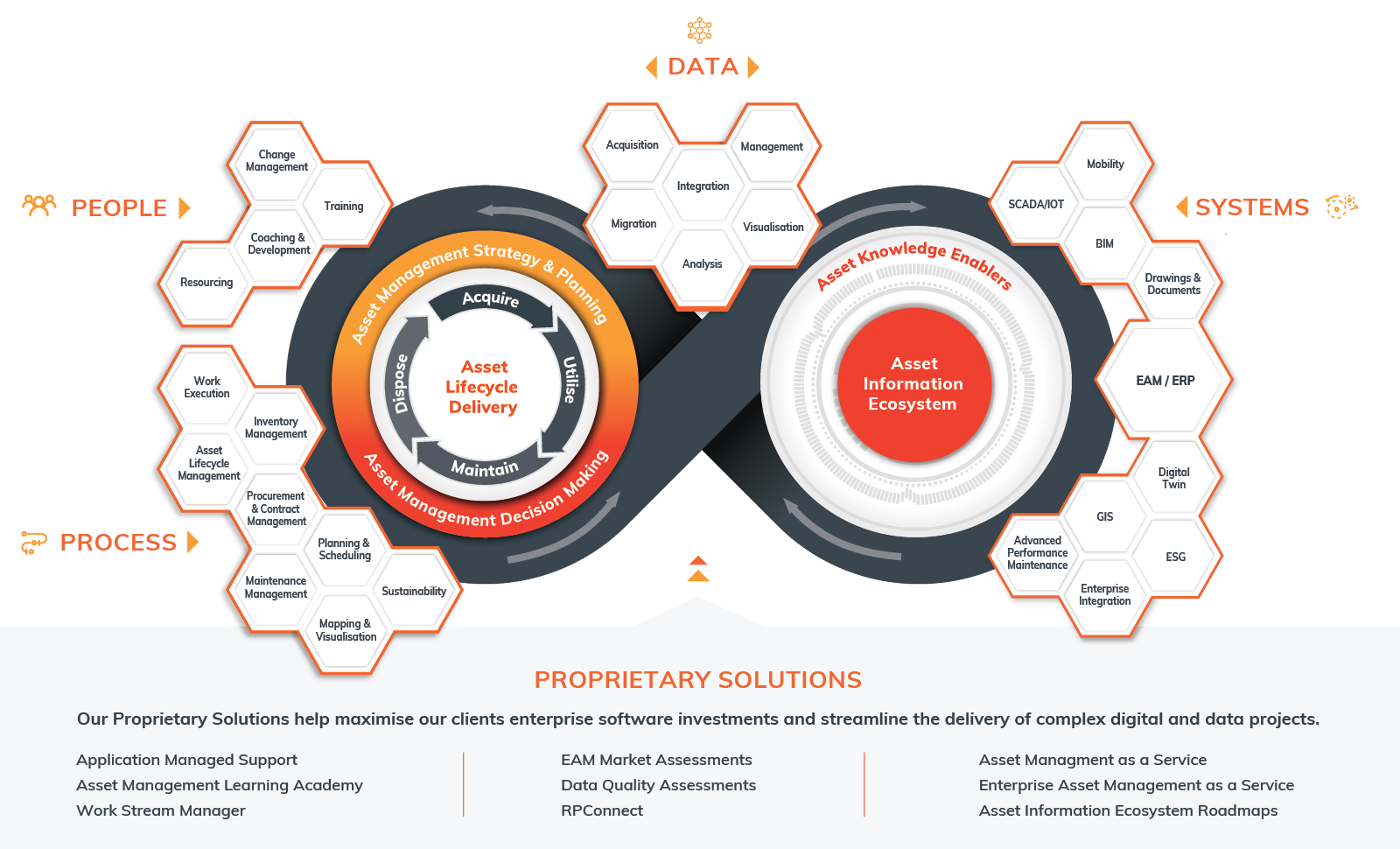

For organisations who rely on business-critical assets, we help optimise performance across the people, process, systems and data elements of asset management.

Drawing on our 20+years of expertise and proprietary solutions that span across the people, process, systems and data elements of asset management, we deliver effective consumption-based maintenance process solutions that help asset-intensive organisations achieve efficiency and sustainability in their operations and supply chains.

We take a collaborative approach to working with our clients to understand where they are in their asset management transformation journey to help them get to where they want to be.

We deliver outcome-driven solutions for our clients based on their unique needs from across the asset management landscape. For clients wanting to outsource their asset management operations, we offer a full end-to-end Asset Management as a Service solution.

Explore our end-to-end asset management capabilities:

People

Process

Systems

Data