At a glance

- Interest is growing in Predictive Maintenance - a data-driven, proactive approach that aims to predict when maintenance is required based on equipment condition.

- Brisbane Airport Corporation worked with Clarita on a Proof of Concept project to assess the capability, feasibility and potential use cases for IBM technologies as an interim step towards predictive maintenance.

- Maximo Application Suite Health and Monitor successfully brought disparate data together into a single, actionable view providing insights that were previously scattered through disparate systems and not easily accessible

About BAC

Brisbane Airport Corporation (BAC), the operator of Brisbane Airport (BNE), proudly takes on the challenge of connecting Australia to the rest of the world every day and building a place where our community can work and play.

They are creating Queensland's future, helping employ thousands of people and fostering cultural and economic growth, contributing more than $4 billion annually to the state's economy.

IBM Maximo has been used to maintain Brisbane Airport facilities and passenger management assets since the early 2000s, together with a variety of IoT devices capturing data on asset condition and performance.

Predictive maintenance opportunity

An innovative culture coupled with the ongoing impact of the COVID pandemic on domestic and international travel means Brisbane Airport is always alert for opportunities to run its business more efficiently and improve the customer experience. For the Asset Optimisation team, that means looking for ways to achieve more timely and precise maintenance interventions, as well as reducing delays or disruption caused by critical asset outages.

Interest in predictive maintenance to address these challenges is growing rapidly across a range of asset-intensive industries, driven by readily available (and reasonably priced) sensors, higher data availability, increased processing power and emerging advanced-analytics talent. Predictive maintenance refers to data-driven, proactive maintenance methods designed to analyse the condition of equipment and help predict when maintenance should be performed. The goal is to better plan or even avoid downtime, increasing uptime while reducing unnecessary preventive and corrective maintenance costs.

Despite strong growth forecasts over the coming decade, there are still many barriers to successfully implementing a predictive maintenance approach, including:

- insufficient, inaccessible, or low-quality data

- inadequate technology, with too few sensors or poor IT infrastructure

- poor prioritisation, as companies lack a clear view of which assets to include in their predictive maintenance programs

Brisbane Airport's Asset Optimisation team were keen to identify how IBM Maximo Application Suite could harness the data already being collected by their existing PLC/SCADA devices as the foundation of a predictive maintenance practice. Although a variety of data streams were available, analysis was completed in many different toolsets, resulting in a fragmented picture of overall asset health, and acting on any insight generated required manual intervention.

A Proof of Concept was established to assess the capability, feasibility and potential use cases for Maximo Application Suite (MAS) Health and Monitor as an interim step towards predictive maintenance. Using a single asset class, the project served to validate the value of a consolidated view of performance data in business processes and assess the expected risks and effort required to move forward with a broader scale implementation.

Proving the value of predictive technologies

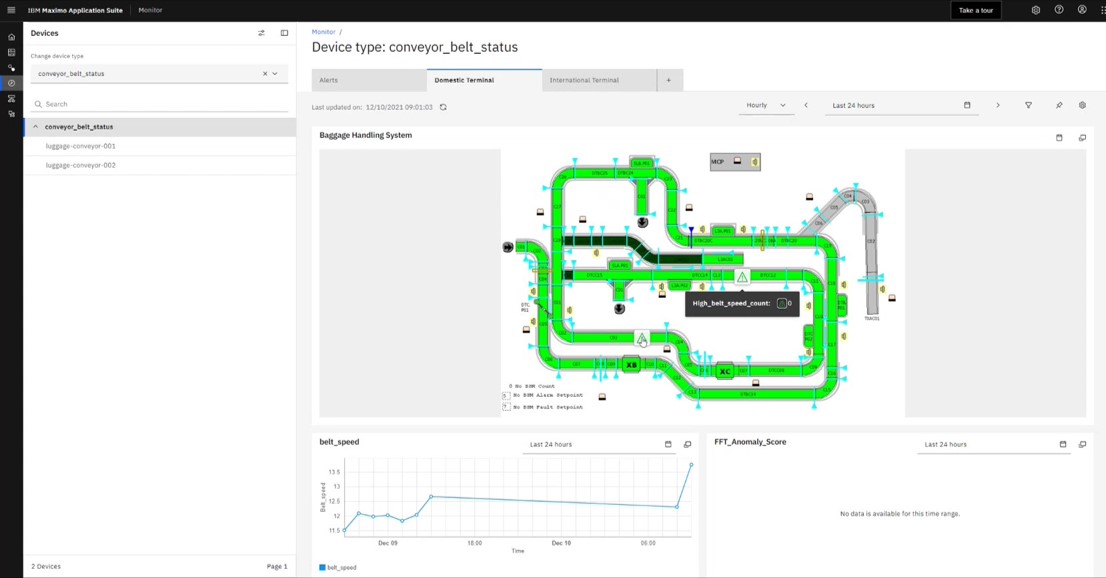

Baggage handling conveyors were selected by the project team as the asset class best suited to addressing the objectives of the project. Clarita established the POC environment, using:

- MAS Manage 8.2 - core Maximo functions, asset register and maintenance records

- MAS Health 8.4 - asset information + asset maintenance + sensor data = asset scoring to facilitate maintenance actions and asset replacement planning

- MAS Monitor 8.6 - provides a path for sensor data collection.

Data was sourced from the airport's existing Maximo database to establish Locations, Assets & PMs within the POC. Brisbane Airport provided access to accumulated alert data for their baggage handling system. The parameters from this source were used as the basis for configuring data simulator devices. The data simulator devices sent transactions to Monitor via RESTful API calls and allowed BAC to visualise real-time data feeds.

Maximo Application Suite

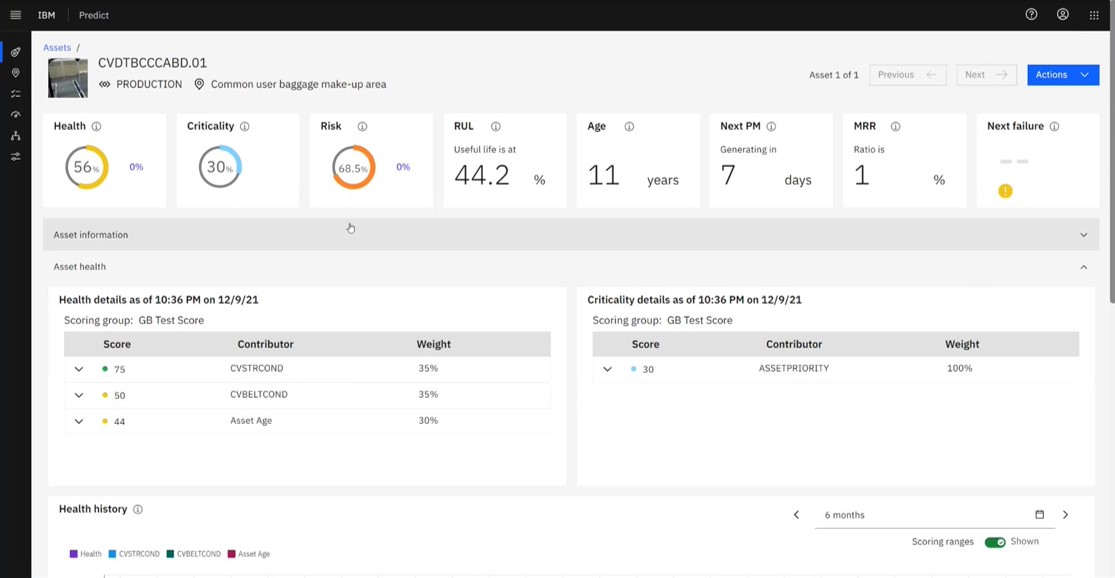

Health scoring parameters include:

- Health % - provides an overall health score allowing users to compare similar assets within an asset class cohort. Scoring parameters are configurable to the asset class providing exceptional flexibility. Score history is maintained to show the trend over time.

- Criticality % - importance of asset

- Risk % - risk score calculated from attribute information

- RUL - remaining useful life

- Age - asset age since installation

- Next PM - days until next PM

- MRR % - maintenance repair costs relative to replacement cost

- Next failure - date predicted when next failure will occur

Conclusions for the journey to predictive maintenance

Maximo (MAS Manage) implementations have historically focused on maintenance activities and asset management, therefore delivering greatest value to the teams responsible for planning and executing those functions.

The project proved that MAS Health and Monitor could successfully bring disparate data into a single container, related back to the core asset management system with work order and cost history, providing a single, actionable view providing insights that were previously scattered through disparate systems and not easily accessible.

Implementing MAS Monitor and Health extends the value of the Maximo investment out across the business:

- operations teams monitoring asset performance

- providing the data necessary for reliability engineering teams to conduct replacement planning

- informing evolution of maintenance strategies and SAMP (as opposed to just executing them)

The ability to view trends and receive alerts when performance is tracking towards a performance threshold was found to be a significant advantage over standard condition monitoring functions in the existing Maximo implementation, which only issues alerts once a threshold is met or exceeded.

For Brisbane Airport, integration of data feeds to support Monitor and Health functions was found to be straight forward. The tradeoff between improved insight and investment in configuring data sources makes it an effective interim step on the journey to Predict.

Clarita's recommendations for other asset intensive organisations keen to move towards a predictive maintenance model through incremental rather than radical change are:

- Select a suitable asset class to get started with

The benefits of adopting a predictive maintenance approach can not always be justified for every asset class. Factors like criticality, cost to replace, failure history, ease of access and current maintenance costs all contribute to the cost/benefit equation. Use your maintenance strategy to identify which critical assets to start with. - Identify the right data

Correlation is not causation, so it's important to identify data that is related to the cause of failure, rather than the result of it. For example, rising temperature in a refrigeration unit indicates that something has gone wrong, but compressor run time may indicate that maintenance is required before failure occurs. - Establish access to the right level of data

Although data security is always a challenge, particularly if you're starting with a stand-alone proof of concept, establishing access to a sufficiently granular data feed for calculating asset health scores is essential. Predictive maintenance solutions are designed to process the huge quantities of data generated by sensors and many, in fact, learn from it. Feeding your model with filtered or modified data will curb your predictive maintenance potential.